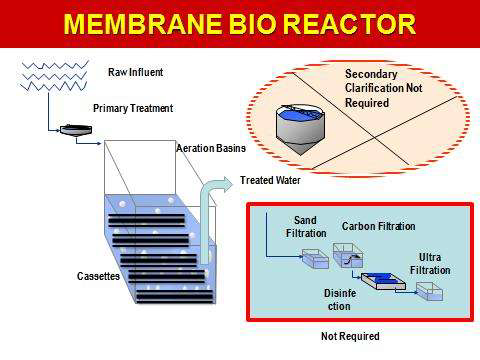

MBR TECHNOLOGY

Enables Operation of Biological Plants at a very high MLSS which means

1. Biological aeration tank size 1/3rd compared of conventional system.

2. Existing biological plants can be retrofitted to treat 3 times the volume of water or BOD.

3. Sand filter, Carbon Filter, Micron Filter & Ultrafiltration are not required. MBR accomplishes

all functions.

4. Easily cleanable membranes. Can be done manually. No more mysterious.

- Submerged Membrane Technology.

- Individual sheets can be cleaned.

- Individual sheets are replaceable. No need to change entire module.

- Product can be directly reused or processed with RO plant downstream.

- Option of mounting the module within aeration tank or a separate tank.

- To degrade recalcitrant organics, bacterial ECM & enzymes are precious and are always maintained within aeration tank. No escape of these materials with treated water.

- Aeration Biomass always kept intact.

- Completely Automatic Systems controlled by PLC.

- No need for permeate back flush.

- Better utilisation of permeate.

- Saves space.

- Guaranteed Membrane Life and performance.

- Sturdier construction compared to hollow fiber module.

- Does not damage easily.